Biphenyl diphenyl ether

Keywords:

Category

产品介绍

Product Description

Biphenyl diphenyl ether mixture heat transfer oil is a high thermal stability gas/liquid dual-use high-temperature synthetic organic heat carrier, which is a eutectic mixture composed of 26.5% biphenyl and 73.5% diphenyl ether. It can be used as a liquid-phase heat transfer oil, or it can be used as a gas-phase heat transfer oil in the temperature range of 257℃-400℃ by using its evaporation-condensation characteristics. It is widely used in the CSP solar thermal power generation industry and the chemical fiber industry.

Main Features

High Thermal Stability

The biphenyl produced at high temperatures is a guarantee of its good thermal stability.

High Recognition

As the first heat transfer fluid to appear on the market, its longevity is enough to illustrate customers' recognition and love for it.

Gas-Liquid Two-Phase

It can be used in liquid state at 12-400°C, or in gaseous state at 257-400°C to achieve higher temperature control requirements.

Product Packaging

200kg drums or ISOTank

Typical Data

| Maximum allowable use temperature/℃ | 400 |

| Appearance/- | Clear and transparent, no suspended matter |

| Crystallization Point/℃ | 12.2 |

| Auto-ignition Point/℃ | 617 |

| Flash Point (Closed Cup)/℃ | 118 |

| Flash Point (Open Cup)/℃ | 124 |

| Purity/% | 99.97 |

| Conradson Carbon Residue/(Mass Fraction)/% | 0.01 |

| Sulfur Content/(Mass Fraction)/% | Less than 0.001 |

| Chlorine Content/mg/kg | 2 |

| Acid Value/(calculated as KOH)/mg/kg | 0.01 |

| Copper Strip Corrosion/(100℃,3h)/Grade | 1a |

| Water Content/mg/kg | 54 |

| Water-soluble Acids and Alkalis/None | None |

| Pour Point/Report | / |

| Density/20℃/kg/m³ | 1062.9 |

| Ash Content/(Mass Fraction)/% | Less than 0.002 |

| Boiling Range/℃ | 255-258 |

| Kinematic Viscosity/0 ℃ | 7.923(0°C) |

| /40°C | 2.502(40°C) |

| /100°C | 1.003(100°C) |

| Deterioration Rate/% | 4.8 |

The above data is based on laboratory sample testing and is not the same for all samples. Contact sales staff for detailed information.

Customer sampling

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated triphenylbenzene-light component

Factory

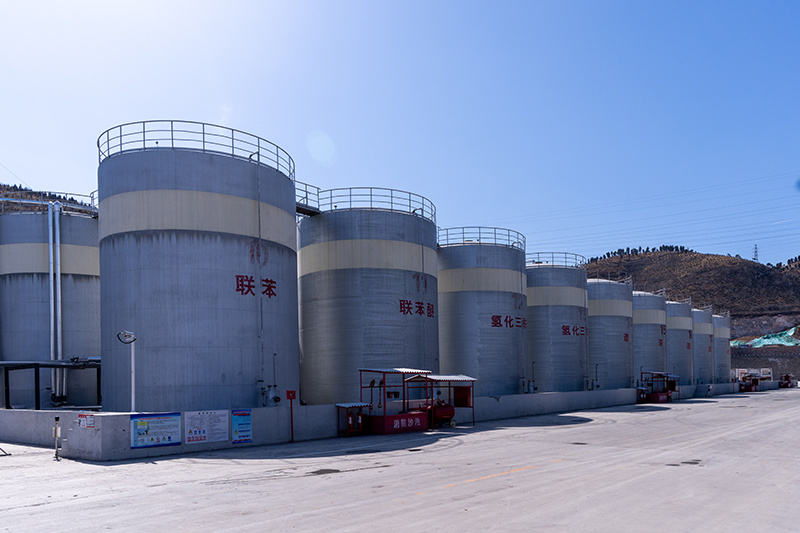

Panoramic view of the factory area

Office building

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

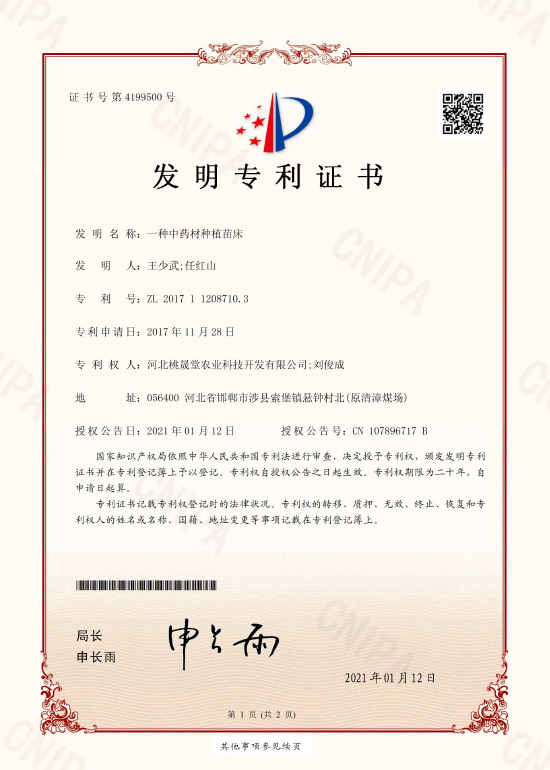

Invention patent

Chemical raw material mixer

A preparation method for catalytic hydrogenation of saturated cashew phenol

A production method of high-purity bisphenol S

A preparation method for high-temperature synthetic thermal oil

A preparation method of biphenylether

Preparation method of trihydroxymethylaminomethane

A synthesis method of biphenyls, pharmaceutical intermediates

A seedbed for planting Chinese medicinal materials

Site survey

Previous:

INQUIRY

RELATED PRODUCTS