Triphenylene

Keywords:

Category

产品介绍

Product Description

Hydrogenated terphenyl is an excellent high-temperature heat transfer oil for liquid phase, with high thermal stability, oxidation resistance, and low vapor pressure. It is a liquid phase heat transfer oil used for heat transfer at high temperatures, and can provide reliable operation for several years even at a working temperature of 345 ℃. Our hydrogenated terphenyl passed the 350 ℃ thermal stability test of China Special Equipment Inspection and Research Institute in 2013.

L-QD350 organic heat carrier (hydrogenated terphenyl) is a high-temperature synthetic heat transfer oil, the main component of which is a mixture of partially hydrogenated terphenyl isomers. It is obtained by partial hydrogenation of a mixture of ortho-, meta-, and para-terphenyls in different proportions. Average molecular weight: 252 Appearance: Slightly yellow transparent oily liquid. Low freezing point, low permeability at high temperature, can be used in liquid phase for a long time under 350° conditions.

Main Characteristics

High Thermal Stability

The terphenyl mixture formed at high temperatures exhibits ultra-high thermal stability.

Low Coking

It is not easy to form solid particles and coke deposits, and it degrades into low molecular volatile substances, which can be self-drained through the system.

Low Vapor Pressure

The saturated vapor pressure at high temperature is low, reducing the system burden and ensuring reliable system operation.

Product Packaging

200kg drums or ISOTank

Typical Data

| Item |

Test Results |

| Maximum Allowable Operating Temperature/℃ |

350 |

| Appearance/ - |

Clear and transparent, no suspended matter |

| Autoignition Point/℃ |

386 |

| Flash Point (Closed Cup)/℃ |

170 |

| Flash Point (Open Cup)/℃ |

181 |

| Sulfur Content/(Mass Fraction)/% |

Less than 0.001 |

| Chlorine Content/mg/kg |

Less than 1 |

| Acid Value/(in terms of KOH)/mg/kg |

0.02 |

| Copper Strip Corrosion/(100℃, 3h)/Grade |

1a |

| Water Content/mg/kg |

63 |

| Water-soluble acids and bases/None |

None |

| Pour Point/Report |

-30 |

| Density/20℃/kg/m³ |

1005.3 |

| Ash Content/(Mass Fraction)/% |

Less than 0.002 |

| Distillation Range/Initial Boiling Point/℃ |

244 |

| /2%/℃ |

335 |

| Residue Carbon/(Mass Fraction)/% |

Less than 0.01 |

| Kinematic Viscosity/0°C |

1204 |

| /40°C |

29.89 |

| /100°C |

3.912 |

| Deterioration Rate/% |

8.4 |

Customer sampling

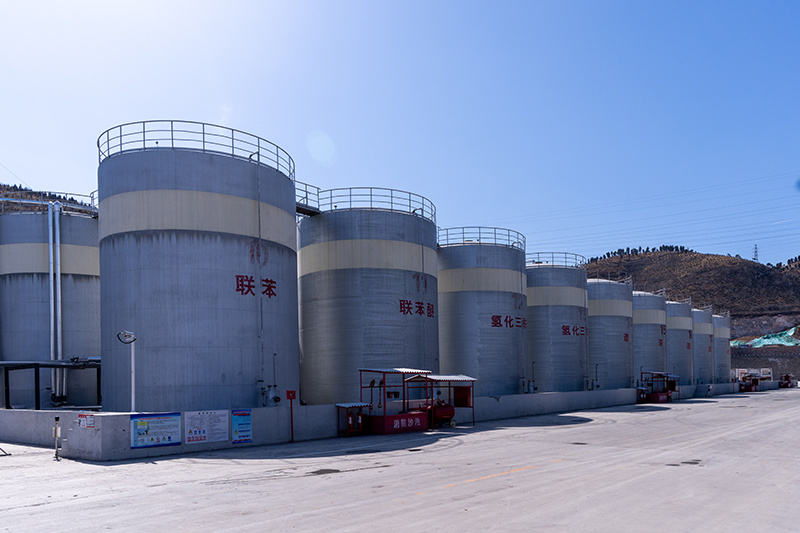

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated triphenylbenzene-light component

Factory

Panoramic view of the factory area

Office building

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

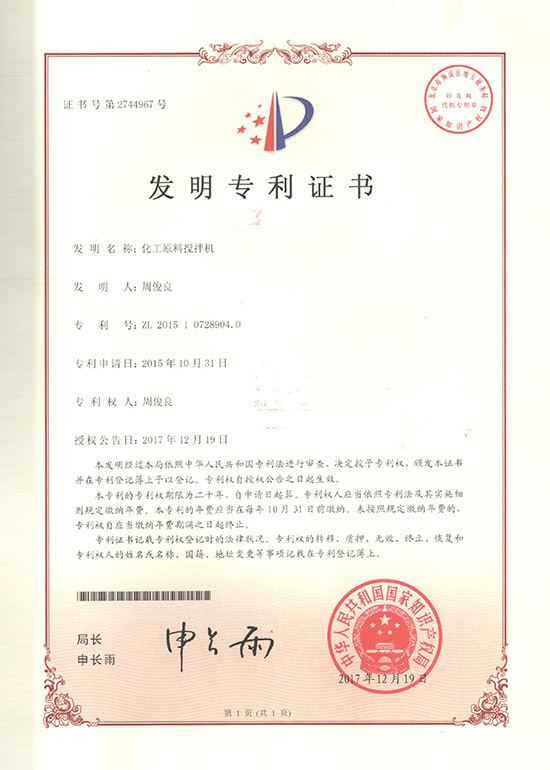

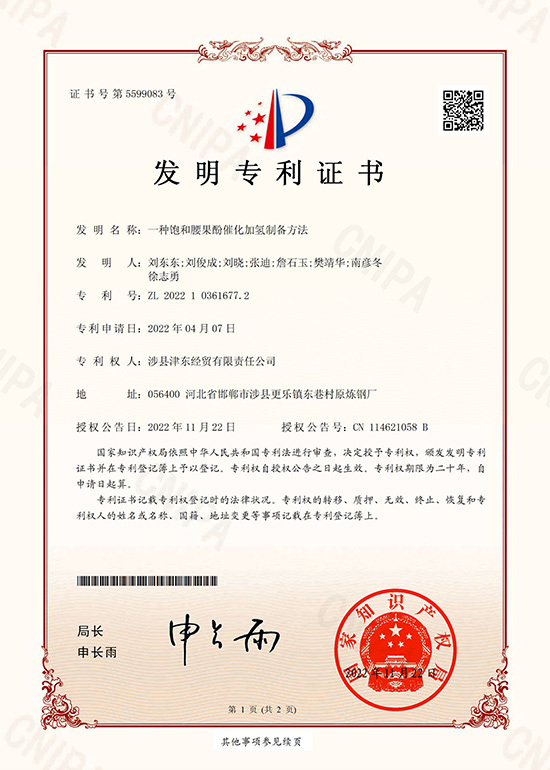

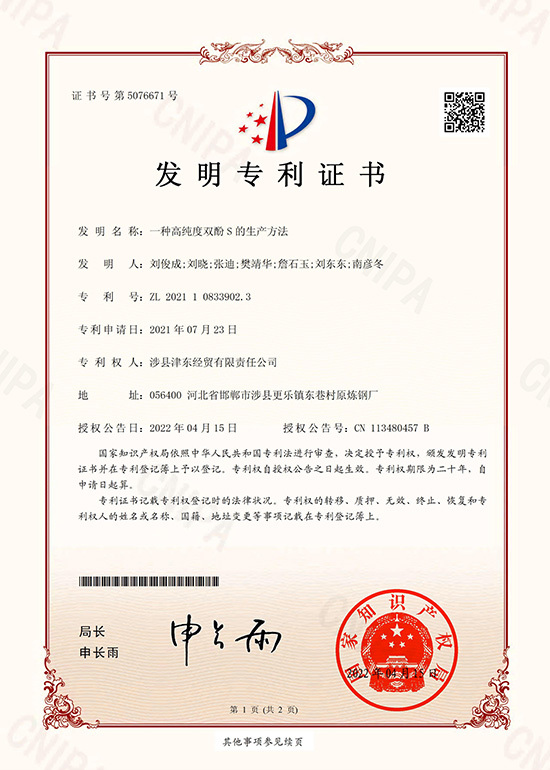

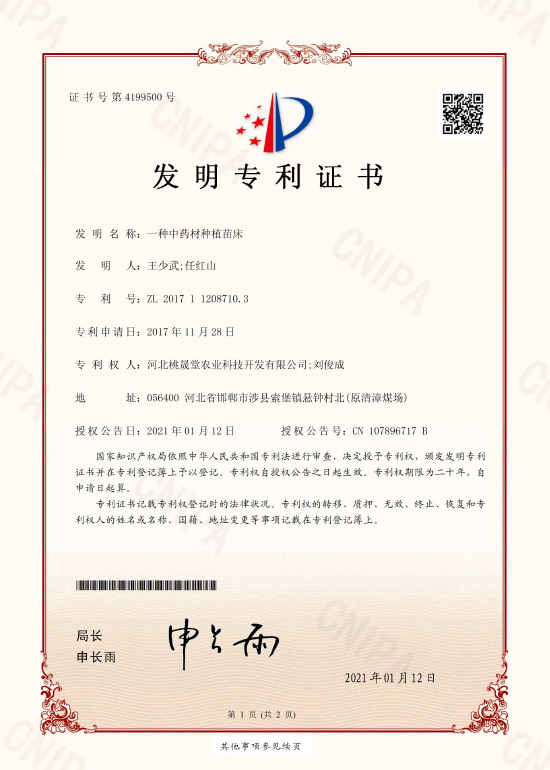

Invention patent

Chemical raw material mixer

A preparation method for catalytic hydrogenation of saturated cashew phenol

A production method of high-purity bisphenol S

A preparation method for high-temperature synthetic thermal oil

A preparation method of biphenylether

Preparation method of trihydroxymethylaminomethane

A synthesis method of biphenyls, pharmaceutical intermediates

A seedbed for planting Chinese medicinal materials

Site survey

Previous:

Next:

INQUIRY

RELATED PRODUCTS