PEKK Resin

Keywords:

Category

产品介绍

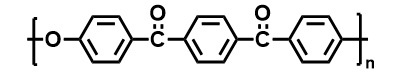

PEKK (Polyetherketoneketone) is a white or light yellow granular solid with a glass transition temperature between 143-162 ℃ and a melting point between 343-390 ℃. It has excellent chemical resistance, soluble in concentrated sulfuric acid, trifluoroacetic acid, etc., but insoluble in water and common organic solvents. The English name of 聚醚酮酮 is polyetherketoneketone, abbreviated as PEKK. The structural formula is as follows:

The molecular structure of polyaryletherketone contains rigid benzene rings and flexible ether bonds. Among the polyaryletherketone series, the lower the ratio of ether bonds to ketone groups (E/K) in the molecular chain, the higher the melting point and glass transition temperature. From the structural formula, the ketone/ether ratio is as high as 2, increasing the rigidity of the main chain. Therefore, PEKK has better heat resistance than PEEK and possesses excellent comprehensive properties.

2. Performance and Synthesis

PEKK can be synthesized by two different methods: nucleophilic substitution and electrophilic substitution. Nucleophilic substitution involves complex reaction conditions and high costs, which are unfavorable for commercial production. Electrophilic substitution is simpler to operate, has a straightforward process, and lower cost, making it the most commonly used method for producing PEKK.

Electrophilic substitution uses aromatic diacyl chlorides and diphenyl ether as reactants, with dichloroethane as the solvent and AlCl3 as the catalyst. Through Friedel-Crafts acylation, PEKK with higher molecular weight can be obtained. The performance of PEKK is closely related to the type of acyl chloride monomer used during synthesis. Using terephthaloyl chloride as the raw material produces PEKK with the highest glass transition temperature and melting point among the main polyaryletherketone varieties. Using isophthaloyl chloride results in lower melting and glass transition temperatures. In actual production, a mixture of terephthaloyl chloride and isophthaloyl chloride is often used to produce PEKK with performance better suited to requirements.

3. Product Advantages

1. Mechanical Properties

Under the same processing conditions, compared to PEEK, PEKK has over 30% higher elastic modulus, over 30% higher tensile strength, and over 80% higher compressive strength.

2. Chemical Stability

PEKK has good chemical stability and can resist corrosion from many chemicals, maintaining stability in various chemical environments.

3. Wear Resistance

PEKK has good wear resistance, making it suitable for manufacturing parts and components that require wear resistance.

4. Biocompatibility

PEKK has good biocompatibility, excellent osseointegration, and surface antibacterial properties, making it suitable for medical applications, especially implants and medical device manufacturing.

5. 3D Printing Adaptability

Due to its amorphous nature, low melting point, and very low shrinkage rate, PEKK is a material highly suitable for 3D printing, enabling high-precision molding and providing possibilities for customized production.

4. Main Applications

1. Aerospace: PEKK has strong radiation resistance and can be used as coating material for special wires in airplanes and satellites. With excellent mechanical properties, it can be made into heat-resistant connectors and weather-resistant, creep-resistant antenna covers for aircraft. Its outstanding flame retardancy results in low smoke and toxic gas emissions. Carbon fiber and glass fiber reinforced composites based on PEKK are commonly used to manufacture aircraft cabins, door handles, control sticks, and helicopter tail fins.

2. Automotive Industry: PEKK materials have good chemical corrosion resistance, wear resistance, and insulation. Coating PEKK on substrate surfaces by electrostatic spraying or flame spraying can improve the efficiency of powertrain components and reduce overall system costs. It has broad application prospects in vacuum pump parts, bearings, gaskets, seals, clutch gears, and even replacing stainless steel and titanium for engine liners.

3. 3D Printing and Medical Fields: PEKK's unique properties make it an ideal high-performance polymer for FFF (Fused Filament Fabrication) or SLS (Selective Laser Sintering) processes. It can be further customized by controlling molecular weight and adding additives such as glass fiber, carbon fiber, or carbon nanotubes. In the medical field, it is commonly used to manufacture sterilization components, implants, spinal and trauma devices, and reusable surgical and dental equipment.

4. Energy and Petroleum: PEKK polymers can withstand extreme high pressure, high temperature, corrosive chemicals, and other harsh environments. They are used to make compressor valve plates, piston rings, seals, and various chemical pumps, valves, and downhole equipment parts, significantly improving the service life and reliability of downhole tools, enhancing operational efficiency, and reducing costly downtime.

5. Electronics and Electrical: Due to good insulation and low dielectric constant, using PEKK materials can make electrical appliances more energy-efficient, quieter, more compact, and extend warranty periods.

5. Product Packaging

25KG bag packaging

6. PEKK Performance Data

| Item | Unit | Test Value |

| Density | g/cm3 | 1.29 |

| Viscosity | dL/g | 0.89dL/g |

| Tensile Strength | MPa | 108~130 |

| Glass Transition Temperature | ℃ | 143-162 ℃ |

| Melting Temperature | ℃ | 343-390 ℃ |

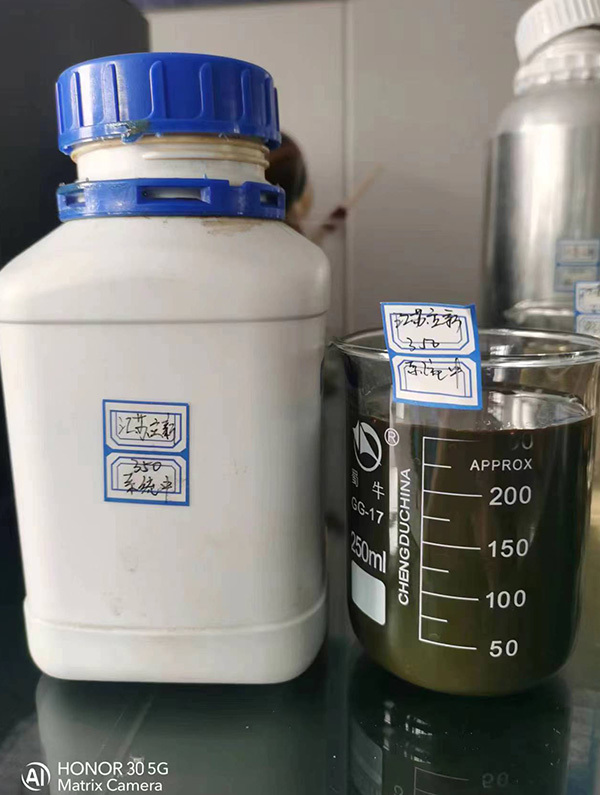

Customer sampling

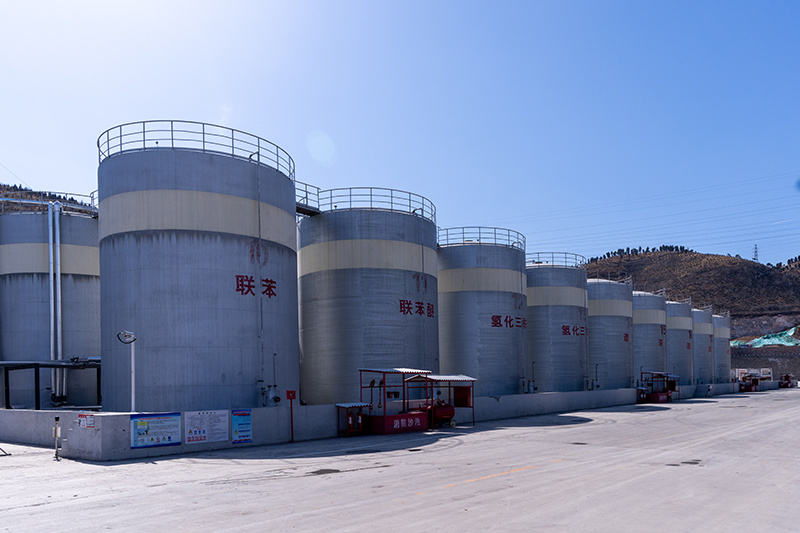

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated triphenylbenzene-light component

Factory

Panoramic view of the factory area

Office building

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

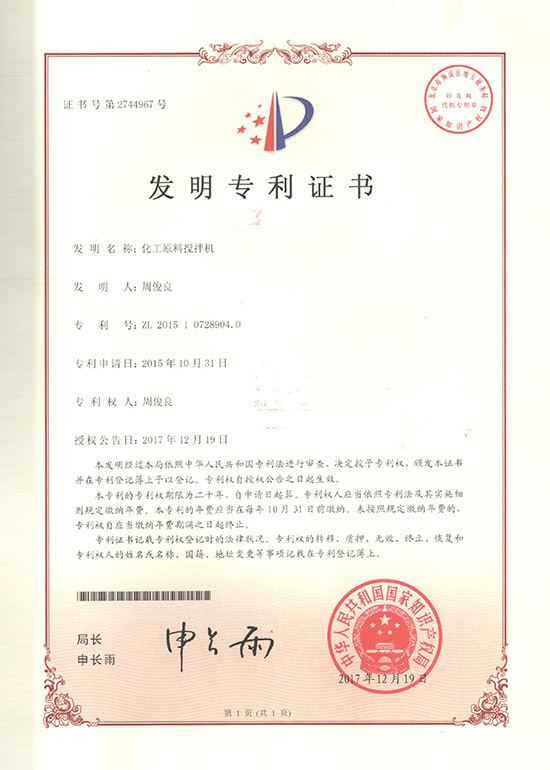

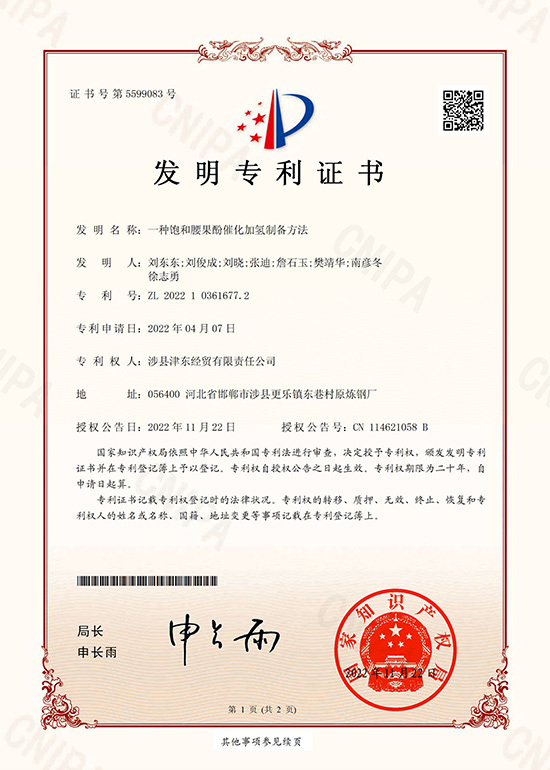

Invention patent

Chemical raw material mixer

A preparation method for catalytic hydrogenation of saturated cashew phenol

A production method of high-purity bisphenol S

A preparation method for high-temperature synthetic thermal oil

A preparation method of biphenylether

Preparation method of trihydroxymethylaminomethane

A synthesis method of biphenyls, pharmaceutical intermediates

A seedbed for planting Chinese medicinal materials

Site survey

Previous:

Next:

INQUIRY

RELATED PRODUCTS