For triphenyl ion exchange resin

Keywords:

Category

产品介绍

Product Description

The anion exchange resin of triphenylbenzene is a light yellow polymer particle. The core material characteristics are as follows: it has the function of exchanging anions and is a type of functional ion exchange resin with a polyaryl non-arylether structure; it has stable physicochemical properties, with a viscosity of 100 mPa·s in 10wt% dimethyl sulfoxide (DMSO) solvent at room temperature (RT), and is soluble in various polar solvents such as N,N-dimethylformamide (DMF) and methanol. The dissolved system is uniform, facilitating subsequent processing.

Main Applications

After pretreatment such as dissolution and defoaming, the triphenylbenzene anion exchange resin can be cast into high-performance anion exchange membrane materials. Due to high ion conduction efficiency and strong chemical stability, this membrane material has irreplaceable application value in energy conversion, water treatment, energy storage, and other fields. Specific scenarios and functions are as follows:

Water Electrolysis for Hydrogen Production As the core separator and ion conduction component of the water electrolysis system, this anion exchange membrane can effectively separate the cathode and anode regions, preventing the mixing of hydrogen and oxygen that could cause safety risks; it also efficiently conducts OH⁻ and other anions, reducing ohmic losses during electrolysis, significantly improving hydrogen production efficiency (especially suitable for alkaline water electrolysis technology), and reducing electrolyte consumption, ensuring hydrogen product purity above 99.9%.

Carbon Dioxide Electroreduction: In CO₂ electroreduction devices, the membrane material maintains the acid-base balance of the reaction system, preventing local pH anomalies in the electrolyte during the reaction; it also directionally conducts anions, providing a stable ionic environment for the reaction, reducing the generation of by-products such as H₂, assisting in the efficient conversion of CO₂ into high-value chemicals like carbon monoxide (CO) and formic acid (HCOOH), thereby improving carbon conversion efficiency and product selectivity.

Seawater Electrolysis Targeting the high salt and impurity ion characteristics of seawater, this membrane material has good salt corrosion resistance and can resist damage to the membrane structure caused by ions such as Cl⁻ in seawater; it also prevents impurity ions in seawater from entering the core electrolysis area, avoiding electrode poisoning, ensuring continuous and stable operation of seawater electrolysis for hydrogen or chlorine production, and reducing dependence on scarce freshwater resources.

Seawater Desalination Compatible with electrodialysis seawater desalination technology, the membrane material selectively allows anions such as Cl⁻ and SO₄²⁻ in seawater to pass through, working synergistically with cation exchange membranes to achieve efficient separation of salt ions in seawater; compared to distillation, energy consumption is reduced by 30%-50%, producing freshwater that meets drinking water standards (TDS ≤ 1000 mg/L) or industrial water (such as boiler feedwater), suitable for large-scale seawater desalination projects in coastal areas.

Electrodialysis Besides seawater desalination, it is widely used in industrial wastewater treatment and material purification: in electroplating wastewater treatment, it can precisely remove anions corresponding to heavy metal ions such as Cr⁶⁺ and Ni²⁺, achieving compliant wastewater discharge or water resource recycling; in the food and pharmaceutical industries, it can be used for amino acid separation and sugar solution desalting (e.g., glucose solution desalting and purification), improving product purity and quality, meeting food-grade and pharmaceutical-grade standards.

Fuel Cells As the electrolyte membrane of anion exchange membrane fuel cells (AEMFC), it can replace traditional alkaline electrolytes, conducting OH⁻ anions and providing ion channels for the electrochemical reaction of hydrogen and oxygen; it also isolates fuel (hydrogen) and oxidant (air), preventing crossover, enhancing the energy density of the cell (up to 600 Wh/kg or more) and long-term operational stability, suitable for portable power supplies, vehicle power, and other scenarios.

Flow Batteries In energy storage devices such as all-vanadium flow batteries and iron-chromium flow batteries, the membrane material effectively prevents the cross-mixing of active substances (such as V²⁺/V³⁺, V⁴⁺/V⁵⁺) in the positive and negative electrolytes, avoiding capacity decay; it also ensures efficient conduction of anions in the electrolyte, reducing polarization losses during charge and discharge, improving charge-discharge efficiency (up to 80% or more) and cycle life (over 10,000 cycles), suitable for energy storage projects supporting new energy power generation (photovoltaic, wind power).

Product Packaging

2Kg Bag

Typical Data

| Serial Number | Test Item | Test Result |

| 1 | Color | Light Yellow |

| 2 | Viscosity | 100 mPa·s (10wt%@DMSO, RT) |

| 3 | Ionic Conductivity | ≥120 ms·cm⁻¹ (80℃) |

| 4 | Ion Exchange Capacity (IEC) | 2.2 mmol/g |

| 5 | Counter Ion | Cl⁻ |

Customer sampling

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated terbiphenyls-in the system

Filling-hydrogenated triphenylbenzene-light component

Factory

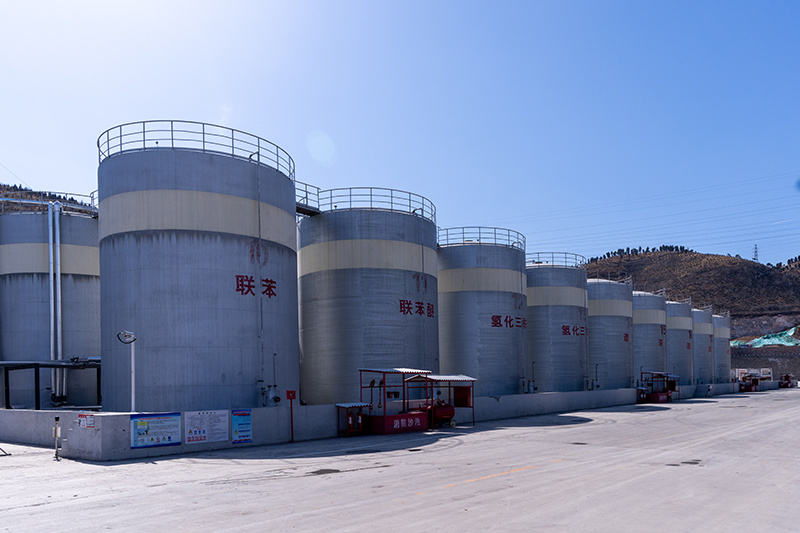

Panoramic view of the factory area

Office building

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

Production workshop

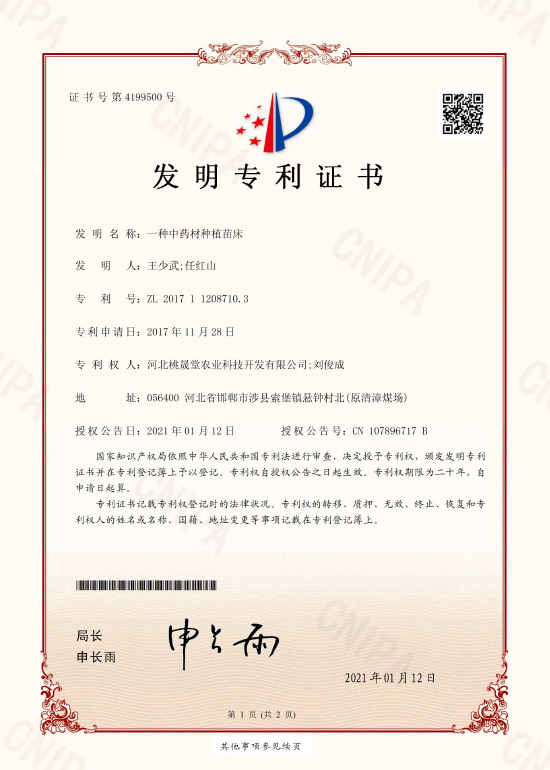

Invention patent

Chemical raw material mixer

A preparation method for catalytic hydrogenation of saturated cashew phenol

A production method of high-purity bisphenol S

A preparation method for high-temperature synthetic thermal oil

A preparation method of biphenylether

Preparation method of trihydroxymethylaminomethane

A synthesis method of biphenyls, pharmaceutical intermediates

A seedbed for planting Chinese medicinal materials

Site survey

Previous:

Next:

INQUIRY

RELATED PRODUCTS